Pipe notching looks simple—until you try it. Most beginners struggle not because they lack tools, but because they repeat the same small mistakes that compound into bad fitment, ugly welds, and wasted material.

The good news: every one of these mistakes is easy to fix once you know what to look for. If you're new to pipe coping, start with our complete guide to understanding pipe coping.

Mistake #1: Guessing the Notch Angle

The problem:

Many beginners eyeball the angle or assume everything is a 90° joint. In reality, most fabrication work involves compound or shallow angles.

Why it matters:

Even a few degrees off creates gaps that are hard to fill cleanly with weld.

How to fix it:

- Measure the actual angle between the tubes

- Use an angle finder or digital level

- Generate a notch based on the real angle, not the assumed one

Learn more about how angles affect joint strength in our pipe saddle joint guide. Need angle conversions? Try our unit converter tool.

Mistake #2: Cutting Directly on the Line

The problem:

Beginners often cut exactly on the marked line, leaving no room for adjustment.

Why it matters:

If you overcut even slightly, you can't put material back.

How to fix it:

- Rough cut just outside the line

- Sneak up on the final shape with a flap disc

- Test fit often

This gives you control and cleaner results.

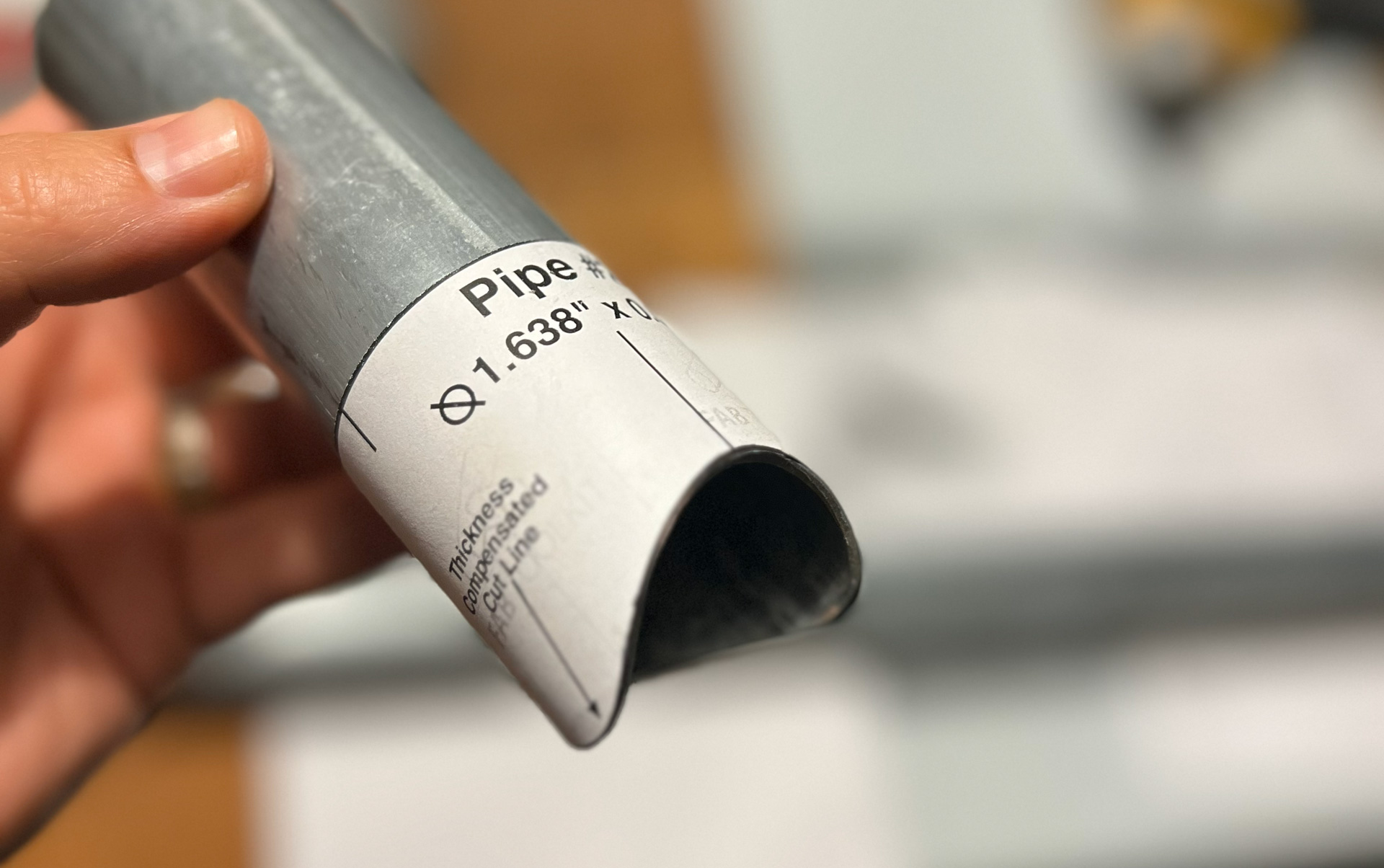

Mistake #3: Not Wrapping Templates Tight Enough

The problem:

Loose or wrinkled paper templates distort the notch shape.

Why it matters:

A tiny wrinkle at the seam can translate into a large gap at the joint.

How to fix it:

- Pull the template tight around the tube

- Align the seam perfectly

- Tape it securely before tracing

Mistake #4: Ignoring Tube Wall Thickness

The problem:

Beginners treat all tubing the same, regardless of wall thickness.

Why it matters:

Thin-wall tube (.065–.083) shows mistakes more clearly and burns through faster. Thick-wall tube is more forgiving.

How to fix it:

- Be extra precise with thin-wall tubing

- Focus on tight fitment before welding

- Use lighter pressure when grinding thin material

Mistake #5: Relying on One Tool Only

The problem:

Some beginners think they must use only a grinder or only a tube notcher.

Why it matters:

No single tool does everything perfectly.

How to fix it:

Use a hybrid approach:

- Template for layout

- Hole saw or grinder for rough cut

- Flap disc for final fit

This combination is faster and more accurate than any single method.

Mistake #6: Not Test Fitting Often Enough

The problem:

Beginners cut too much material before checking the fit.

Why it matters:

You can remove material fast—but correcting mistakes takes much longer.

How to fix it:

- Test fit after every adjustment

- Look for daylight through the joint

- Rotate the tube to check full contact

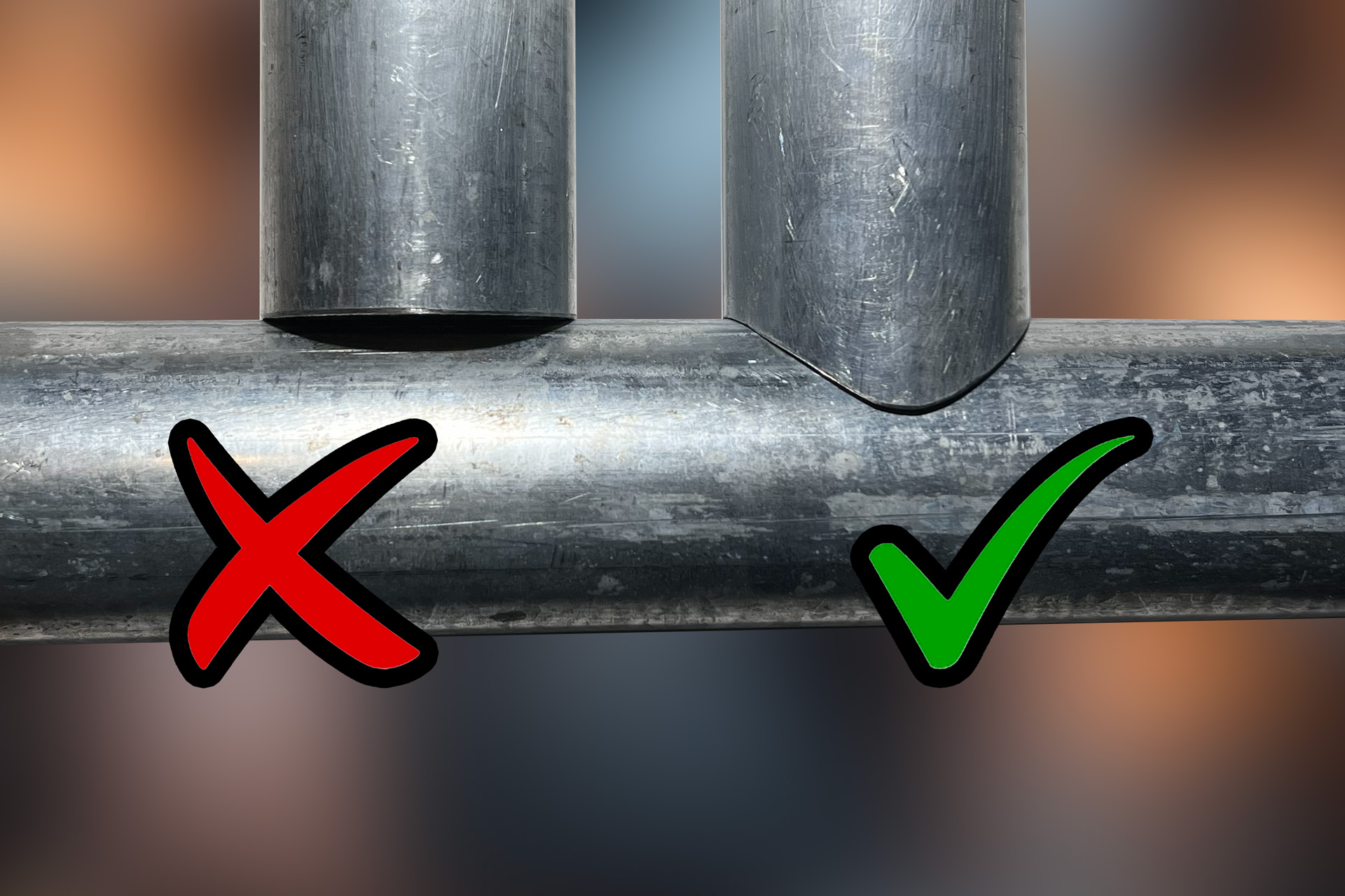

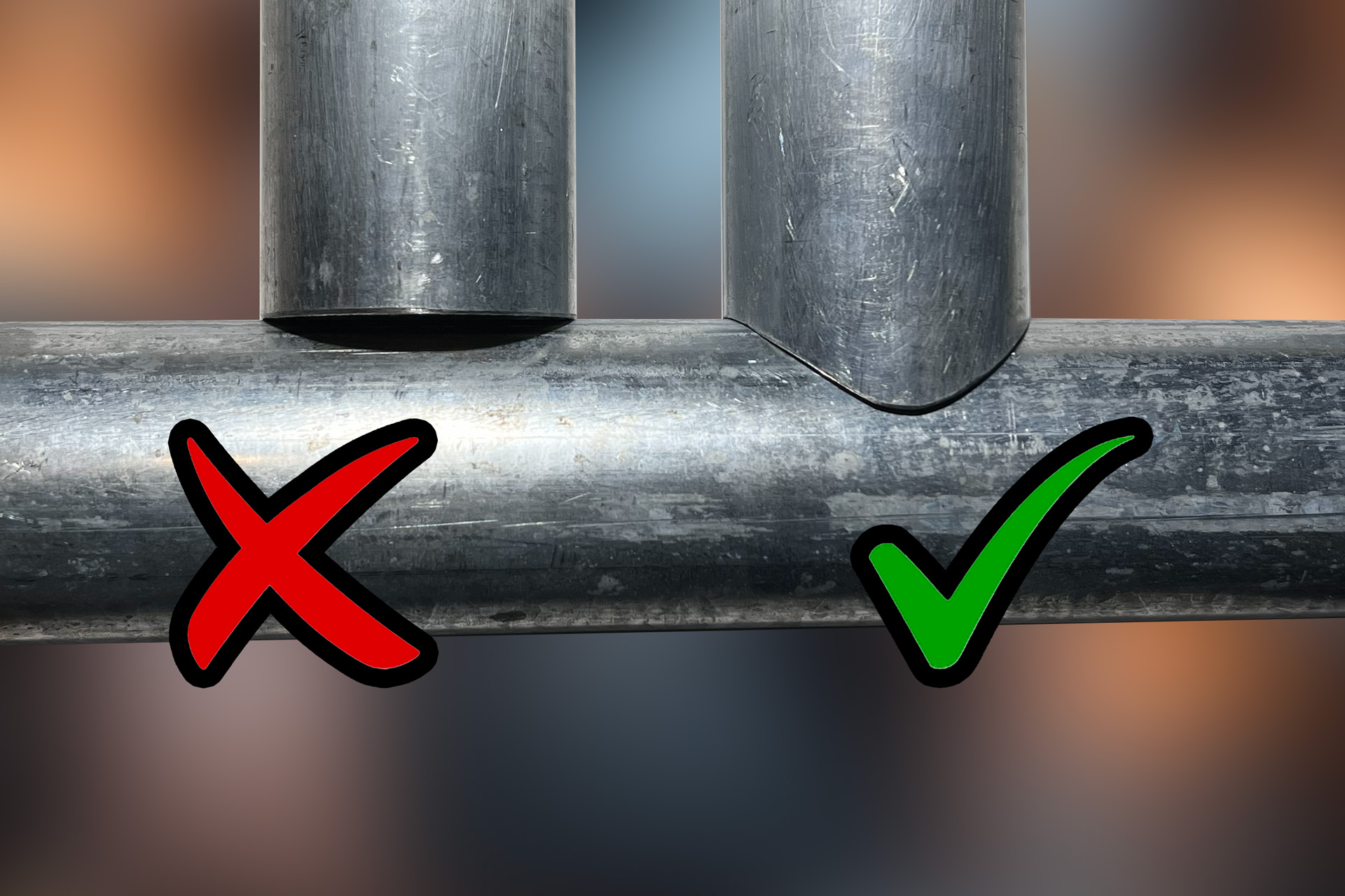

Mistake #7: Trying to Weld Through Gaps

The problem:

Instead of fixing the notch, beginners try to "fill the gap with weld."

Why it matters:

This weakens the joint and creates ugly welds that need grinding.

How to fix it:

- Stop and rework the notch

- Aim for near-perfect contact before welding

- Let the weld join the metal—not fill space

Mistake #8: Skipping Layout Tools Entirely

The problem:

Some beginners try to freehand every notch.

Why it matters:

Freehand notching works—but only after lots of practice.

How to fix it:

Use layout aids:

- Paper templates

- Marking guides

- Simple calculators

They reduce guesswork and speed up learning.

Quick Checklist Before You Cut

Before you notch any tube, ask yourself:

- ✔ Did I measure the real angle?

- ✔ Is my template printed at 100% scale?

- ✔ Is the paper wrapped tight and aligned?

- ✔ Am I cutting slightly outside the line?

- ✔ Am I test fitting often?

If yes—you're doing it right.

Conclusion

Every fabricator makes these mistakes early on. The difference between frustrating results and clean, professional joints isn't talent—it's process.

Slow down, measure accurately, use templates or guides, and let the fit dictate the weld. Fix these common issues and your notches—and welds—will improve immediately.

Related Tools & Guides:

- Pipe Coping Template Generator — Generate precise templates for any angle

- Pipe Miter Template Generator — For straight miter cuts

- Fabricator's Unit Converter — Convert measurements and check pipe sizes

- How to Cope Pipe With Printable Templates

- Pipe Saddle Joint Explained

Want an easier way to lay out accurate pipe notches?

Try our free Pipe Coping Template Generator — no login required.

Launch Tool