Printable tube coping templates are extremely accurate — but only if the shape is transferred to the tube correctly.

Most fit-up issues blamed on "bad templates" actually come from distortion, slipping, or sloppy marking during the transfer step. This guide shows how fabricators reliably move a printed coping pattern onto steel without losing accuracy.

Why the Transfer Step Matters

The template defines the exact saddle shape of the joint. Any error introduced during transfer becomes:

- Gaps at the joint

- Extra grinding

- Poor weld penetration

Accuracy here saves time later.

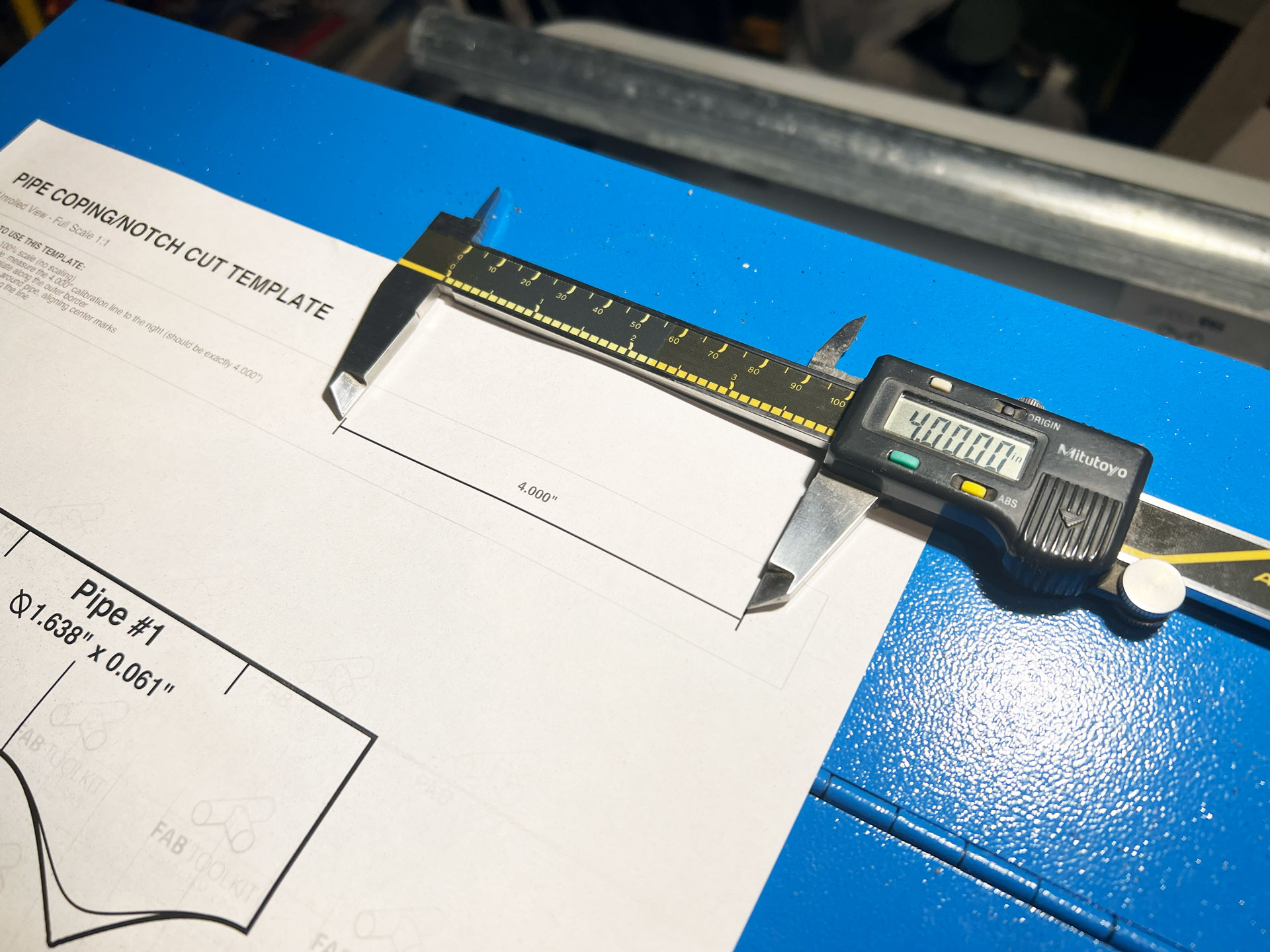

Step 1: Print at True Scale (Do This First)

Before wrapping anything around steel:

- Make sure your printer is set to 100% scale

- Disable "fit to page"

- Verify scale with a ruler if possible

Even a small scaling error will affect the fit.

Paper choice affects how well the template wraps and stays put.

Most fabricators use:

- Standard printer paper for quick jobs

- Light cardstock for repeated handling

Avoid thick paper that resists wrapping around the tube.

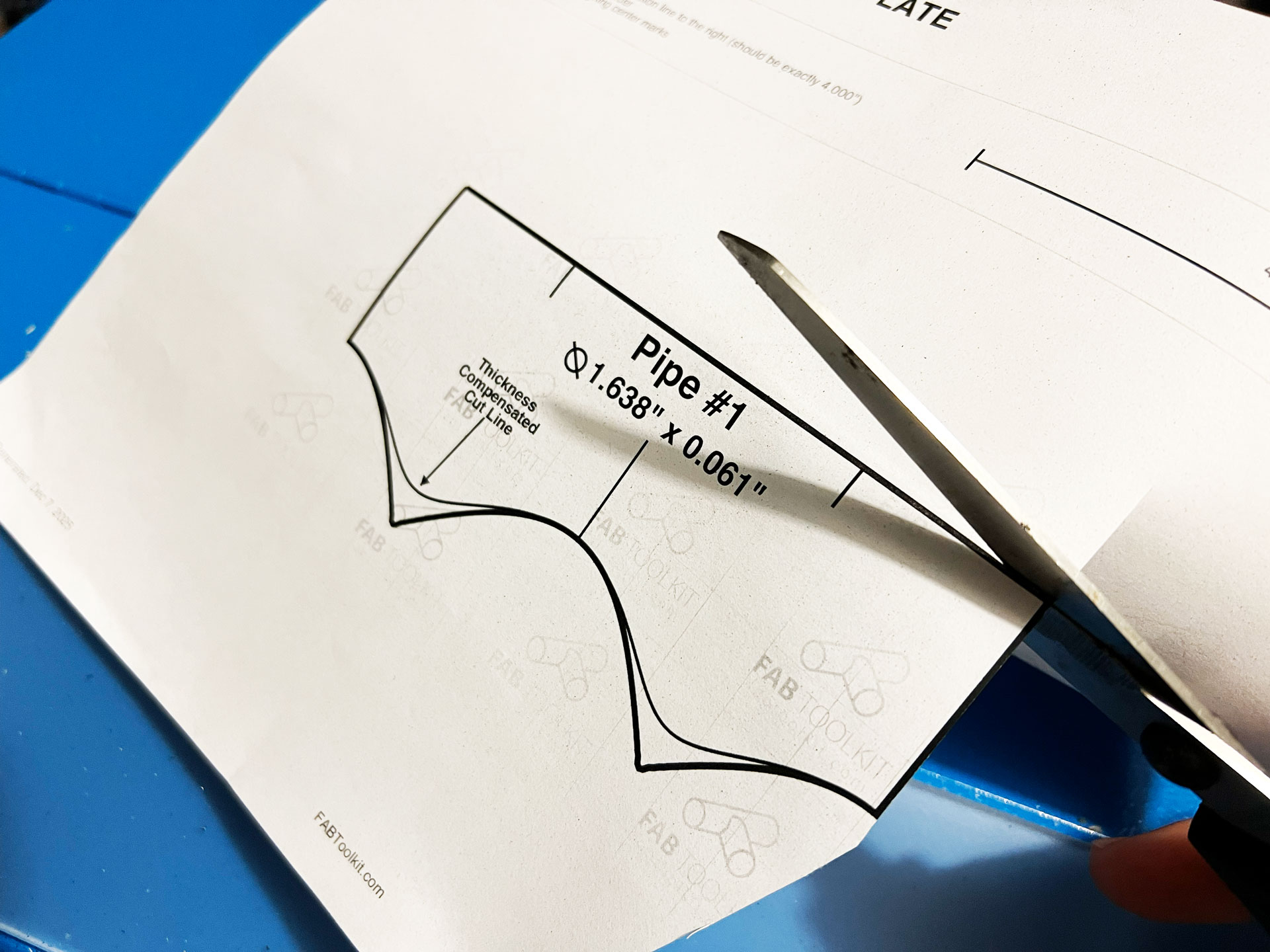

Step 2: Cut out the Template

Use sharp scissors or a utility knife to cut along the printed outline carefully.

Take your time to ensure clean edges — jagged cuts can cause misalignment when wrapping.

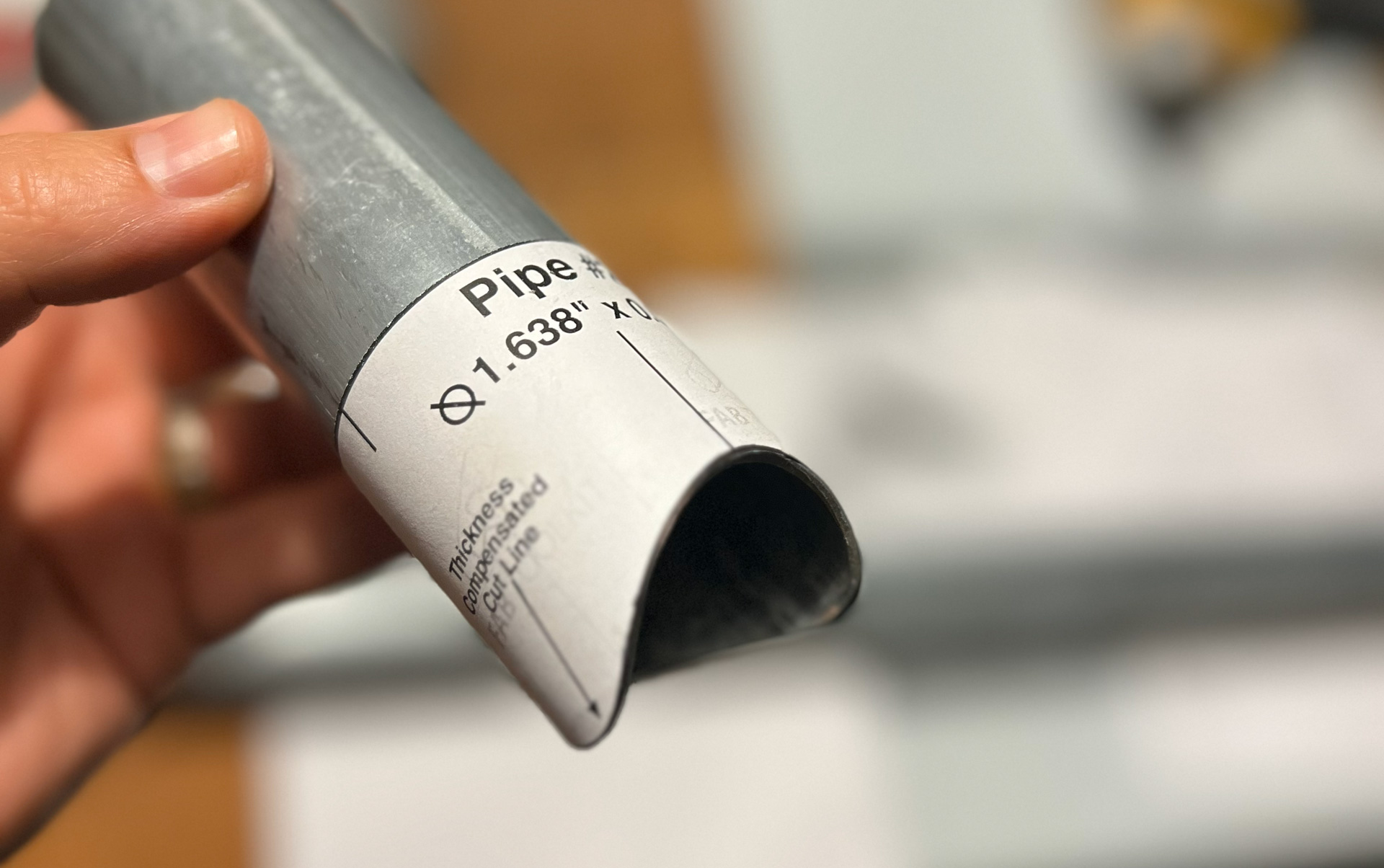

Step 3: Secure the Template Without Distortion

The goal is to hold the template tight to the tube without stretching or skewing it.

Common methods:

- Masking tape

- Light spray adhesive

- A small wrap of painter's tape at the seam

Recommended Option:

Tape should hold the paper flat, not pull it.

Step 4: Mark the Cut Line Cleanly

Use a fine-tip marker or scribe and follow the template edge carefully.

Good options:

- Fine-tip Sharpie

- Paint marker for dark steel

- Scribe for permanent layout

Popular option:

Sharpie Industrial Fine Tip Marker

Avoid thick markers that widen the line and reduce precision.

Generate Your Tube Coping Template

Create precise, full-scale templates for any tube intersection in seconds. Free online tool — no signup required.

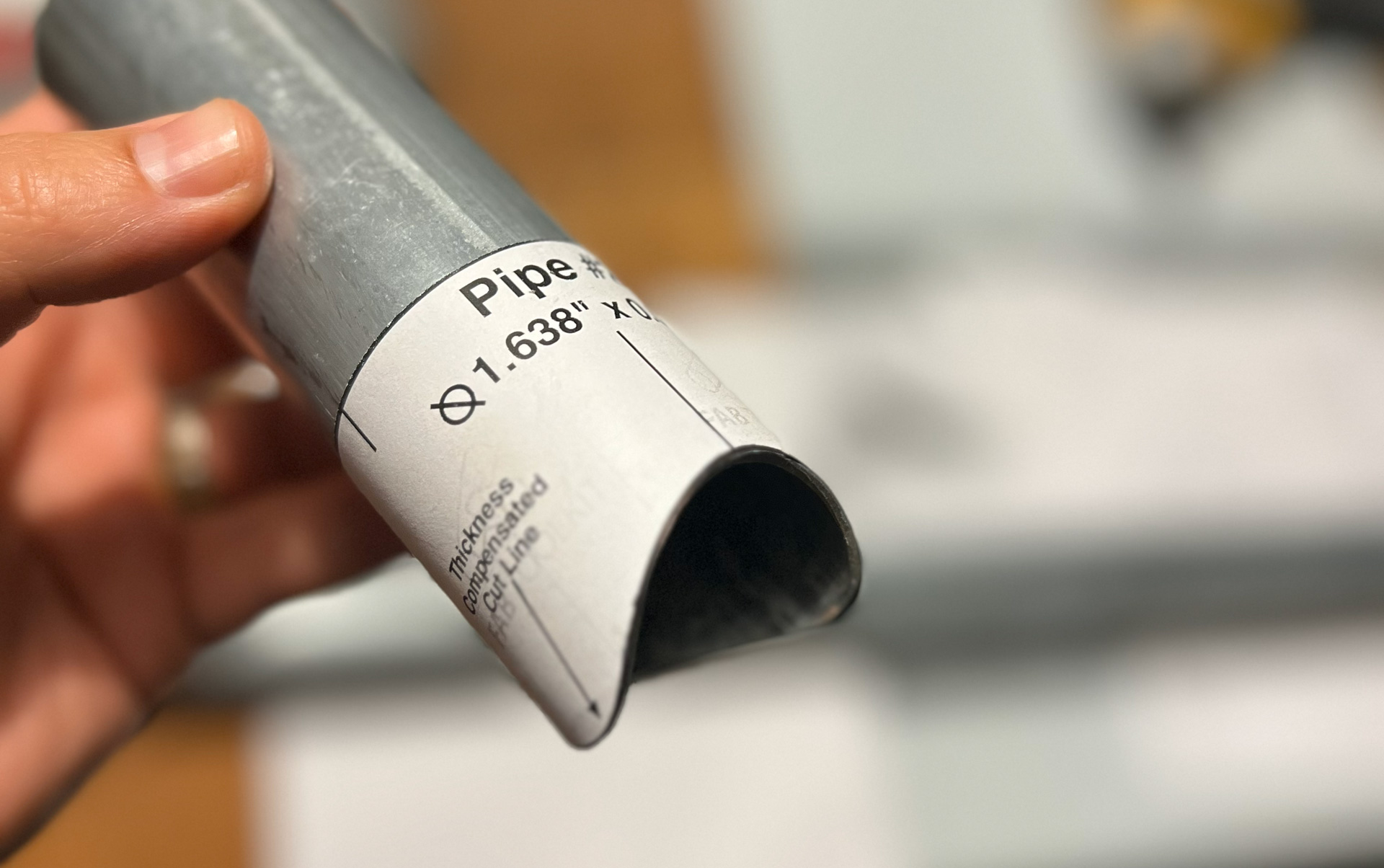

Launch Template GeneratorStep 5: Remove the Template and Inspect

Once marked:

- Remove the paper carefully

- Inspect the line for gaps or overlaps

- Re-mark any unclear sections before cutting

If the line looks uneven, fix it now — not after cutting.

Common Transfer Mistakes (and Fixes)

- Template slipped: Use more tape or lighter adhesive

- Line too thick: Switch to a finer marker

- Distorted wrap: Reprint and align the seam carefully

- Hard to see line: Use a heavier marker or layout fluid

Templates work — but they don't forgive rushed setup.

Why This Method Works So Well

When the template is:

- Printed accurately

- Wrapped evenly

- Marked cleanly

The resulting cut line already matches the mating tube. Cutting becomes execution, not problem-solving.

That's why many fabricators rely on printed coping templates even when other tools are available.

Related Guides & Tools

- Pipe Coping Template Generator

- How to Cope Pipe With Printable Templates

- Pipe Saddle Joint Explained

Ready to Start?

Use our free pipe coping template generator to create precise templates for your next project.

Get StartedNote: This article contains Amazon affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you. We only recommend products we believe will help you achieve better results in your fabrication work.