Not everyone has access to a tube notcher, mill, or dedicated fabrication equipment — and even when they do, setup time and angle math can slow things down.

The good news is: you don't actually need a tube notcher to achieve a tight, professional-quality tube fit. With the right approach, you can get extremely accurate results using basic tools and properly generated coping templates.

This article walks through how fabricators achieve clean tube joints without a tube notcher — and why printable templates are often the simplest path.

Why Tube Fit Matters More Than the Tool

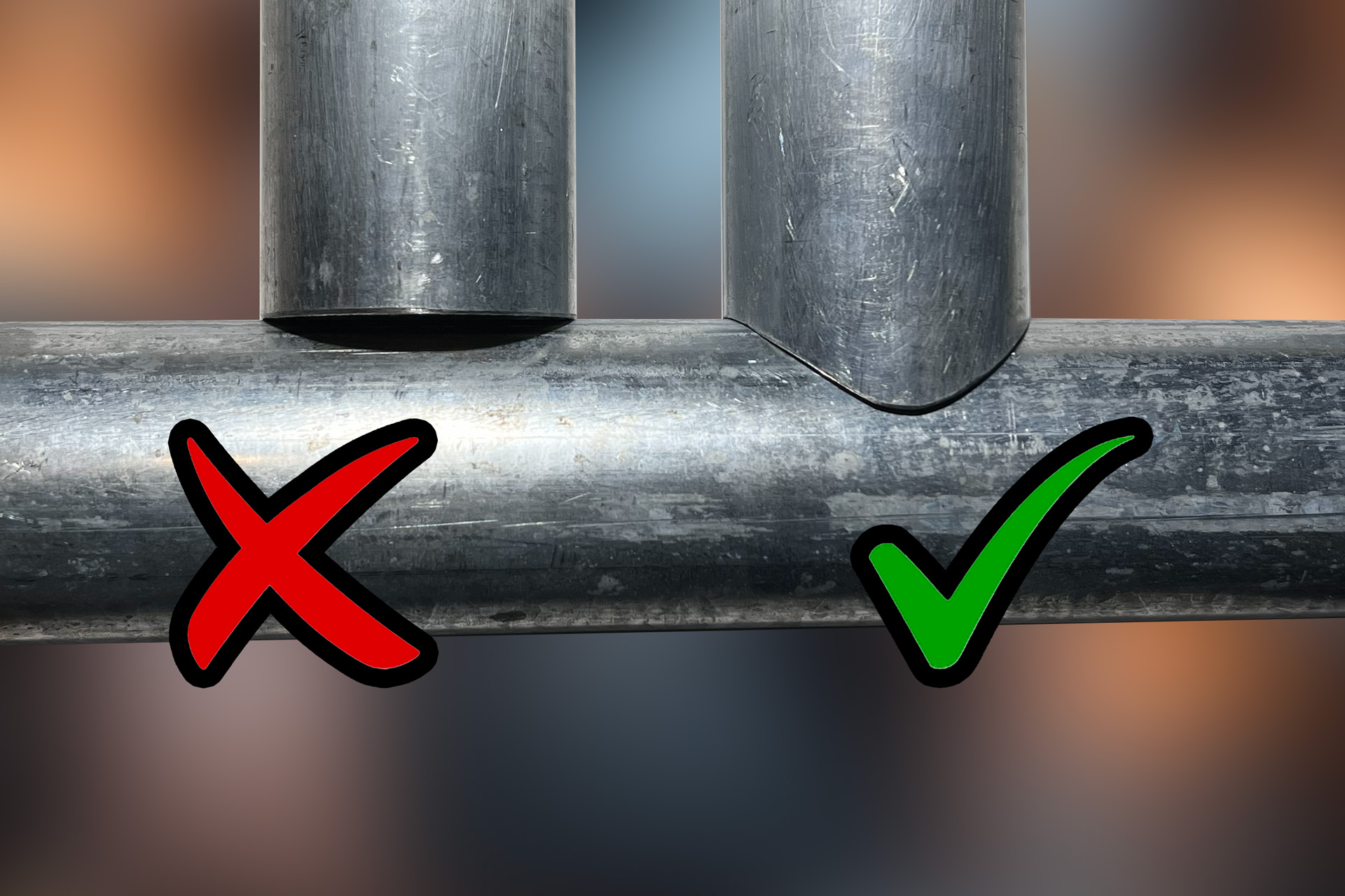

A good tube joint isn't about how the notch was made — it's about:

- Full surface contact

- Minimal gaps

- Consistent alignment through the joint

Poor fit-up causes:

- Excessive weld filler

- Distortion during welding

- Weak joints that crack later

Whether you use a $20 grinder or a $2,000 notcher, accuracy at the joint is what counts.

The Problem With "Eyeballing" Tube Notches

Many beginners try to freehand cope tubes by:

- Guessing angles

- Grinding until "it looks close"

- Tweaking the joint after every test fit

This works sometimes — especially at simple 90° joints — but it quickly breaks down on:

- Shallow angles

- Compound joints

- Roll cage intersections

Small angle errors compound fast, and once material is removed, it's gone.

Why Templates Solve the Hard Part

The hardest part of tube coping isn't cutting — it's knowing where to cut.

Printable tube coping templates remove the guesswork by:

- Calculating the exact saddle shape

- Matching the outside diameter of the mating tube

- Accounting for joint angle automatically

Instead of guessing, you're simply transferring a known-correct shape onto the tube.

That's the key advantage.

Basic Tools You Actually Need

To use tube coping templates effectively, you only need:

- A printer

- Paper or cardstock

- Tape or spray adhesive

- Marker or scribe

- Angle grinder (or bandsaw)

No drill press. No notcher. No math.

How the Process Works (High-Level)

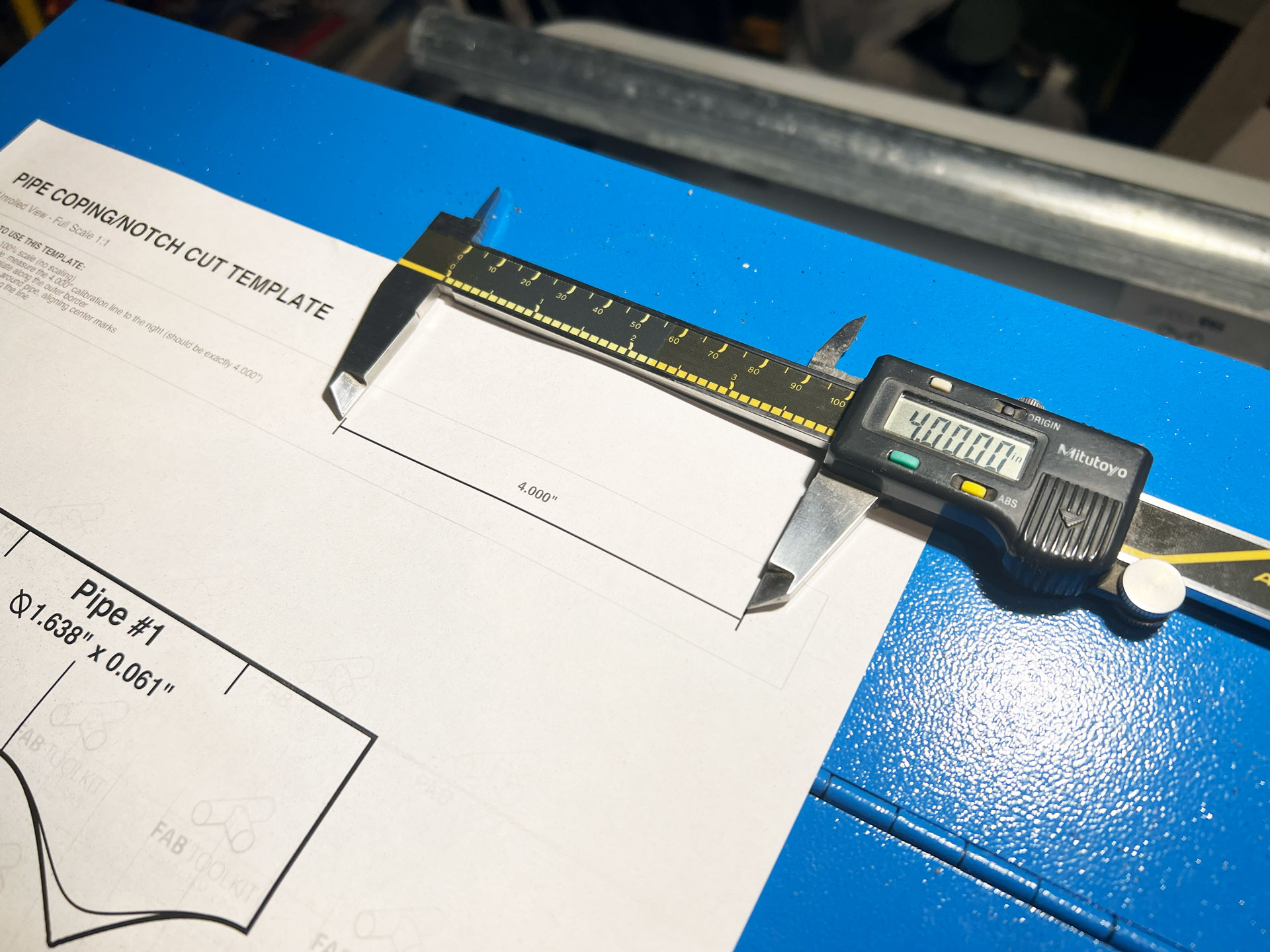

- Measure tube outside diameter

- Determine the joint angle

- Generate the correct coping template

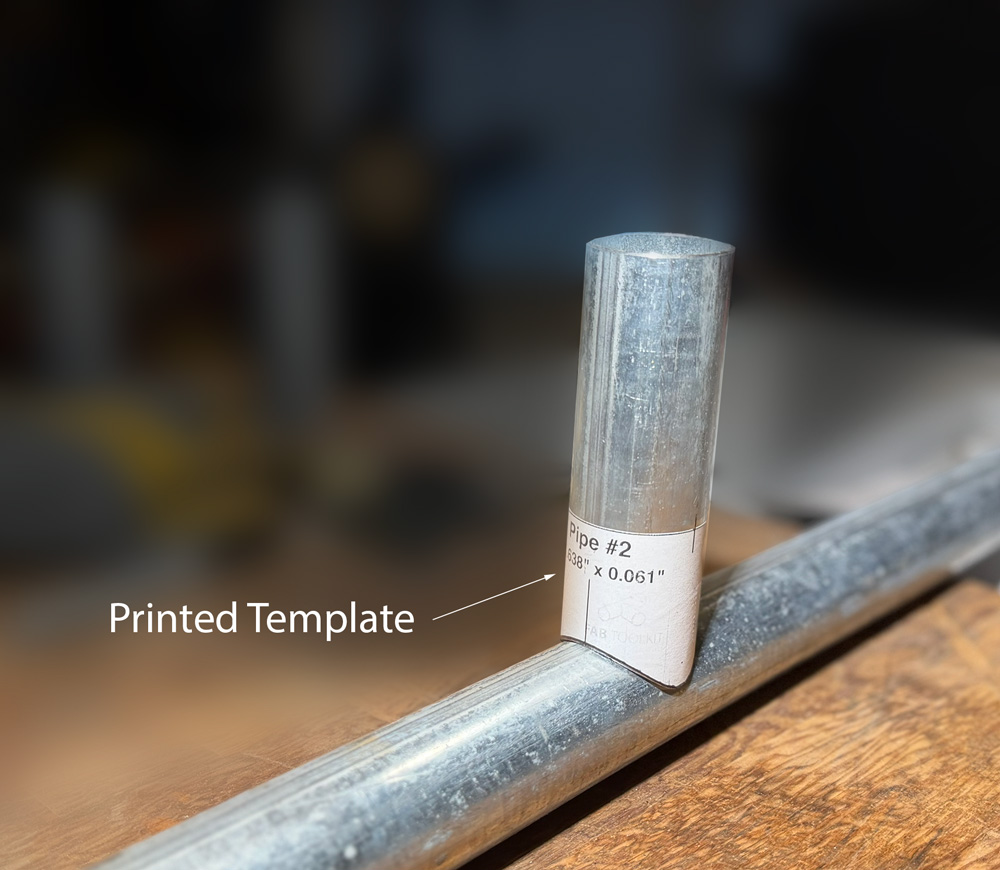

- Print and wrap the template around the tube

- Transfer the shape to the steel

- Cut to the line and lightly clean up

The accuracy comes from the template — not the cutting method.

Generate Your Tube Coping Template

Create precise, full-scale templates for any tube intersection in seconds. Free online tool — no signup required.

Launch Template GeneratorWhy This Works Especially Well for Roll Cages

Roll cages often involve:

- Repeated tube sizes

- Common angles (30°, 45°, 60°, 90°)

- Tight joints where gaps are obvious

Templates shine here because:

- You can reprint identical notches

- Test-fit before committing

- Make small adjustments intentionally instead of guessing

Many fabricators use templates even when they do own a notcher — especially for tricky intersections.

Common Mistakes to Avoid

- Letting the printer scale the template (always print at 100%)

- Wrapping the template unevenly around the tube

- Cutting outside the line "just to be safe"

- Skipping test fits

The template gives you accuracy — patience preserves it.

When a Tube Notcher Still Makes Sense

Dedicated notchers are great for:

- High-volume production

- Repetitive identical cuts

- Thick-wall tubing

But for one-off builds, home shops, and roll cages, templates often get you there faster with less setup.

The Takeaway

If your goal is a clean, professional tube fit, you don't need expensive equipment — you need accurate layout.

Printable tube coping templates eliminate the hardest part of the process and let simple tools do precise work.

That's why they've become a go-to solution for fabricators who care about fit, not flash.

Related Tools & Guides:

- Pipe Coping Template Generator

- How to Cope Pipe With Printable Templates

- Pipe Saddle Joint Explained

Ready to Try It?

Use our free pipe coping template generator to create precise templates for your next project.

Get Started